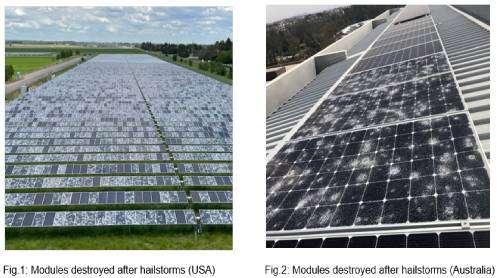

In recent years, The global climate change has led to frequent extreme weather events. meteorological disasters such as hail have become important factors that threaten the safety of Solar plants and the stable income of customers. middle and low latitudes of the northern and southern hemispheres, including Colorado and Texas (USA), Northern Italy, Southern France, Southern China, as well as Central Argentina and Southeastern Australia in the Southern Hemisphere.

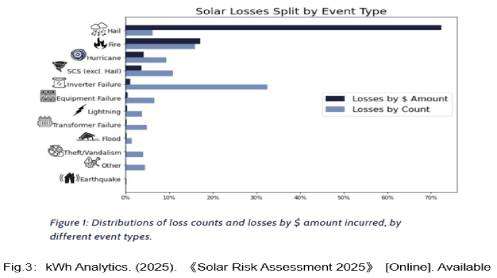

According to an analysis of the loss database in the latest report “Solar Risk Assessment 2025” by kWh Analytics, a US climate insurance service provider, although hailstorms account for only 6% of loss incidents, they cause 73% of total economic losses and an 8% increase from previous years. Statistics show that global PV plant losses due to hail exceeded $1.2 billion in 2024 alone. Europe experienced 11,808 hailstorm events in 2024, a 104% surge from the 5,785 events recorded during 2022-2023. In recent years, many places in China and Australia have also been hit by extremely strong convective weather such as gales, torrential rain, and large hail, and the losses caused by extreme weather to local photovoltaic power plants should not be underestimated.

Confronting this “plant safety killer,” LONGi leverages its profound technological expertise to develop the Hi-MO 9 Ice-Shield module—a global solution engineered to withstand extreme hailstorms. Through material innovation and structural upgrades, this product achieves breakthroughs in both **hail resistance** and **power generation performance**, establishing an impenetrable defense for PV plant safety and returns.

Extreme Hail Resistance: Industrial-Grade Robustness Tested Against Harsh Climates

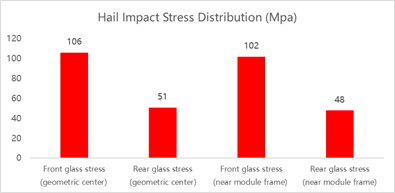

LONGi Hi-MO 9 Ice-Shield module features a comprehensively thickened double-glass structure. Its front glass is 60% thicker than conventional products and undergoes full tempering, boosting impact resistance by 4.5 times. This material strategy, validated through R&D simulations (Fig. 4), ensures optimal hail resilience. The simulation showed that the front glass withstands twice the impact stress compared to the rear glass, which means front-glass strength is more critical from design point of view. For instance, during severe hailstorms, the tempered glass remains as sturdy as a steel plate, while standard module glass may be brittle like paper. The frame utilizes high-strength 6005-T6 aluminum alloy with optimized linear density, significantly enhancing wind load resistance. When associated with a high-load mounting solution, the module withstands loads of +5400/-5400 Pa.

Fig. 4 Simulation Analysis of Glass Stress Distribution in Modules under Hail Impact

In addition, the module has been tested many times and can successfully resist the impact of hail with a diameter of 55 mm and a speed of 33.9m/s, far exceeding the test requirements of IEC standards for 25mm hail. Post-test inspections show no glass cracks or micro-cracks.

Fig.5:RETC 65mm Hail Test Pass Report

High-Efficiency Power Generation: Stable Output Under Extreme Environmental impacts

Built with this robust foundation, the Hi-MO 9 Ice-Shield module integrates LONGi’s proprietary HPBC 2.0 technology, achieving a conversion efficiency of up to 24.8% for outstanding overall power generation. Upgraded with high-load materials to further ensure reliable high performance in harsh environments.

For example, in a 100MW TOPCon plant, the same land area with Hi-MO 9 modules can support 106.4MW capacity. Even in regions with moderate sunlight (assuming an electricity price of 5 cents/kWh), this translates to over $6.5 million in additional lifetime revenue.

Benefiting from BC technology’s unique hot-spot resistance and LONGi’s stringent lifecycle quality control, the Hi-MO 9 delivers higher reliability and lower failure rates at the plant level, making it a trustworthy choice for global customers.

Internationally Certified Reliability

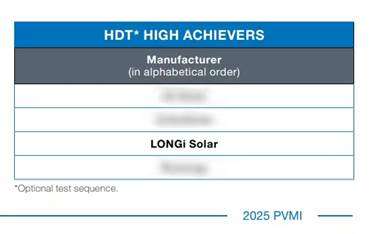

Fig.6:RETC (Renewable Energy Test Center), part of the VDE GROUP. (2025). 2025 PV Module Index Report [PDF].

The LONGi Ice-Shield series modules have been certified by international authorities including RETC, TÜV Rheinland, and TÜV SÜD. It has topped RETC’s High Durability Test (HDT) rankings for years and years. In RETC’s “2025 PV Module Index Report”, LONGi modules received the “Highest Achievement” award across all 13 core tests—including hail sequence validation. These endorsements provide authoritative proof of the series’ reliability in extreme environments, ensuring continuous, stable power generation even amidst hailstorms accompanied by lightning and gales.

Cumulative global orders for LONGi Ice-Shield modules have now exceeded 1GW. Including but not limited to large-scale utility plants in the US Midwest, projects in Australia, Europe. LONGi BC products are building a solid line of defense for photovoltaic power plants in many places around the world, and Hi-MO 9 has become the first choice for customers to rest assured and value throughout the life cycle of power plants.

About LONGi

Founded in 2000, LONGi aims to be the world’s most valuable solar technology company, driving comprehensive energy transition through customer-centric innovation.

As a global industry leader, LONGi invested CNY 5.014 billion in R&D in 2024, representing 6.07% of annual revenue, maintaining technological leadership with dual world efficiency records in monocrystalline silicon single-junction cells and perovskite-silicon tandem cells. LONGi leads in ESG performance with its 2024 MSCI rating upgraded to BBB, achieving the highest ESG scores among A+H-listed semiconductor companies and ranking first in the photovoltaic sector. As China’s first PV enterprise to join RE100, EP100, EV100 and SBTi initiatives, LONGi remains committed to advancing green development and building a carbon-neutral future.

www.longi.com